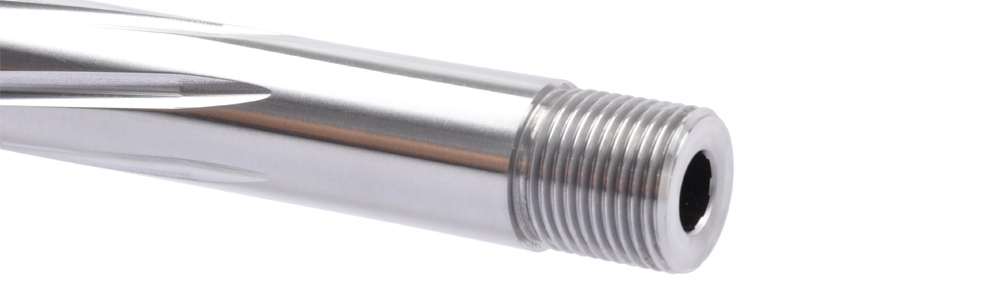

Muzzle Thread:

The muzzle thread is the interface that joins the sound moderator to the rifle barrel. To prevent collision of projectiles against baffles and the resulting loss of accuracy it is absolutely imperative the muzzle is threaded exactly concentric to the centre-line of the bore. A muzzle should never be threaded taking reference only from the outside of the barrel. The bore of the barrel is the governing factor, with many factory rifle barrels being slightly off centre. Threading to tight tolerances can only be achieved by screw cutting on a machine designed to do the job correctly, and NEVER by hand tools. We have years of experience in screw-cutting and are highly skilled in this procedure having threaded many thousands of barrels. We can machine your barrel with a perfectly concentric thread, ensuring you do not encounter problems with your sound moderator or any other muzzle attachment.

Muzzle Thread

Paragraph 21.2 of the Federal Firearms Regulations states that machining a pressure bearing part of a firearm constitutes an act of firearms manufacture and in order to do this the person carrying out the work must have the necessary manufacturer’s permits detailed by paragraph 21 and 26 of the same law. The machining of a muzzle thread is definitely NOT a job for someone who works in a mechanics shop or something you should attempt at home. Threading a rifle barrel belongs firmly in the hands of a qualified and capable Riflesmith. Once a rifle barrel has been threaded it is required, by law, for the rifle to be re-presented for proof at one of the state run proof houses. The proof house tests the durability, safety, dimentional tollerance and correct marking of a firearm, the proof shooting test is carried out with 2 shots with proof ammunition which is loaded to 30% above the maximum recomended pressure for caliber.

We will choose the best method of machining the thread onto your barrel depending on firearm type. Machining will either be done on a Weiler lathe or a 5 axis CNC machining station.

With a muzzle thread cut exactly in line with the bore by Roedale Precision, you have peace of mind that you can fit any kind of muzzle brake or sound moderator with the correct thread type to your rifle.

Each thread that we machine comes with a thread protection cap as part of the service.

Additional Service:

In addition to muzzle threading we also offer other barrel enhancement services

Barrel Shortening:

Many customers choose to have thier barrels shortened before threading, this compensates to some extent the additional length and weight of the added sound moderator. keeping the rifle short and handy. We have had totaly positive experiences with shortened barrels, without exception they shoot better after shortening than before. We use short barreled rifle ourselves and find the slight loss in velocity more than compensated for by improved ergonomics.

Barrel shoprtening can be carried out at the same time as threading.

PLEASE NOTE ! The internationaly recognised method of measuring barrel length is to measure from bolt face to muzzle. This is the method we use. There are however certain Firearms Manufacturers who, for whatever reason differ from this standard and choose to include the breach into this measurement. The difference can be as much as 2″ and causes errors when calculating ballistics.

Measuring barrel length is very simple: Ensure your rifle is unloaded, close the bolt. insert a cleaning rod carefully into the muzzle end, continue until the end of the rod contacts the bolt face, mark the rod at the muzzle and remove. Now measure the length of the rod up to the mark and you have your barrel length.

We are here to help you, should you have any questions on barrel length and its effect on accuracy, velocity and ergonomics.

Barrel Coating:

Many customers decide to have thier barrels coated at the same time as shortening and threading and it makes perfect sense. Why not seal the whole exterior of the barrel against the elements. We can coat your barrel or barrel and action to enable optimal corrosion resistance. We use a 2 part ceramic based technical coating called Ceracoat. This coating is the leading coating product within the firearms industry. it is available in a variety of colours.

Moderator Fitting:

Moderators pruchased from us can be fitted free of charge. We will machine the delrin bush and ensure correct alignment and baffle clearance.

Accuracy & Zero testing:

We offer customers an accuracy and zero testing service. We test your rifle with and without the sound moderator and provide you with a test target and details.

Noise testing for customer and licensing authorities:

We provide a dB testing service for customers and authorities. We can test your rifle with and without a sound moderator and provide a detailed test report.

Chemical barrel cleaning:

The subject of chemicaly cleaning a rifle barrel has lately recieved a lot of interest, we recomend this process is carried out before using lead free ammunition and therafter on a regular basis. We provide a chemical cleaning service using the best cleaning products.

Muzzle Threading Service

How it works:

- We agree on a time window and date for the work to be done. This usually takes between 7 and 14 days, depending on the work load at the proof house.

- The customer delivers the rifle to us personally or by courier. We can also arrange collection.

- We machine the barrel with the correct muzzle thread and deliver it to the proof house for proof testing. Once this is completed, we have it collected. Trade Customers can opt to take care of the re-proof them selves.

- Once the rifle is back with us, we give it a final check and it can then either be collected in person, or we can have it delivered to the door

Please Note:

In the past rifles have occasionally been sent to us in unsuitable packaging. We request that our customers send their firearm in a suitable shipping box or gun box. Firearms arriving in unsuitable packaging will be returned in a gun box and the price of the box will be added to the final invoice. If you don’t have a suitable shipping box you can purchase one from us.

Threading Recommendations:

In Europe and Scandinavia the metric ISO-Fine thread system has become the standard muzzle thread type. American firearms often use imperial threads. In Great Britain, Australia and New Zealand it is common to find both metric and imperial threads. We can machine and fit all types of threads and offer metric and imperial thread types as standard in our sound moderator program. When deciding on which size thread to apply to a muzzle it is imperative to choose carefully. One thing to consider is a 1mm shoulder, or step up to the main barrel outside diameter, is required for a sound moderator to screw back against. One must also have enough wall thickness between bore and thread groove diameter to ensure that the muzzle remains strong enough. Over the years we have seen many incorrect and poorly threaded rifles. We definitely advise against 1/2″ threads on any calibre larger than 6.5mm. If your barrel is too thin at the muzzle, it should be shortened back to provide enough barrel diameter to safely work with. If your rifle isn’t threaded we would recommend the following:

| Airguns and rimfire | 1/2×20 UNF |

| Hunting and sporting firearms with light profile barrels up to cal: 7mm and muzzle <∅14.5mm | M13x1 |

| Hunting and sporting firearms with medium light profile barrels up to cal: .30 and muzzle <∅15.5mm | M14x1 |

| Hunting and sporting firearms with sporter profile barrels up to cal: 9.3mm and muzzle <∅17.5mm | M15x1 |

| Hunting and sporting firearms with semi-sporter weight profile barrels up with a muzzle <∅18.5mm | M17x1 |

| Varmint or Match Rifles with varmint or heavy profile with a muzzle >∅19.0mm | M18x1 |

Common Thread Types:

| 1/2x20UNF | A standard thread on rimfire rifles, airguns and centrefire rifles in cal: .22Hornet, .222Rem, 223Rem etc |

| 1/2x28UNEF | A standard thread on AR15 and many US manufactured firearms up to cal: 6.5mm |

| M14x1 | A standard thread on many European and Scandinavian firearms with muzzle ∅15 bis 16mm up to cal: .30 |

| M15x1 | A standard thread on many European and Scandinavian firearms with Muzzle ∅16 bis 17.5mm up to cal: 9.3mm |

| 5/8x24UNEF | A standard thread on US Manufactured firearms from cal: .223 to .338 |

| 5/8x18UNF | A standard thread in Great Britain, seldom seen elsewhere |

| M16x1 | Seldom used muzzle thread, usually found on single shot break open rifles |

| M17x1 | A standard thread for semi-sporter weight barrels with muzzle from around ∅18mm. Often seen on safari rifles in calibres like .458Win Mag |

| M18x1 | Standard thread for varmint and other heavy barrels with muzzle ∅ 19 to 22mm |

| M18x1.5 | A standard thread on sniper rifles such as the AIAW |

There are many other threads on rifle barrels, however the above are the most common types found in Europe.

General Information regarding firearm condition:

Submitting a Firearm to the Proof is like taking a car for the annual MOT Test. Old and poorly serviced firearms can have hidden defects that come to light during a Proof Test & Inspection. The Proofhouse test the durability and safety of a firearm and shoot it with 2rds of 30% increased pressure loads. You know the condition of your firearms better than anyone and you should consider which are best suited to use with a shound moderator. Old and heavily used firearms as well as some of the stoppage susceptible civilian type semi automatics are not the best choice. Ask your self what is the most cost effective route in the long run, does it make sence to invest in work on an old and tired rifle or is it better to buy something more modern? There are some excellently accurate and dependable rifles available today at some excellent prices. We can offer you a complete Rile-Scope-Moderator package. Most modern firearms are however well suited to use with moderators.

We expect you to deliver your firearm to us in a safe and functional condition. We understand that you are not a gunsmith and during threading to do take a look at the firearms we work on and any noticable faults will be reported to the owner and a joint decision can be made on the next step. We do however not have the time during a threading job to carry out a complete examination of ordnance incuding a range test. We rely on the Proof House to do this. If you require us to carry out a Pre-Proof Test & Inspection then you should book this additionaly.

If your firearm does not pass the proof test this can lead to extra costs that you will be required to pay. We cannot be held responsible for breakages or failures occuring during proof and the Proofhouse accept no responsibility (just as a vehicle workshop accept nor responsibility if your engine breaks down during high reving for an emissions test). 99% of all firearms have no problems passing the proof test, if you are however unsure about the condition of your firearm or its suitability for use with a sound moderator, please ask our advice.